How it is made?

Diatomite Handmade Product Description

Definition:

Handmade crafts

It is an art and craft with a unique artistic style that is made by hand labor. It is different from the arts and crafts of mass production of standardized daily-use handicrafts in a mechanized way by large industries.

Handmade diatomite products are those that are made by hand by the operator. Mechanical tools may be used during this period, but the direct manual work of the operator remains the most important source of the finished product.

Features:

Handmade diatomite products are mainly made of natural materials diatomaceous earth and clay and are able to be made in unlimited quantities. It is practical, beautiful, artistic, decorative, and functional.

- Practicality: through diatomite product, clay as the main raw material of the paste or prefabricated embryo, with different mold shapes as the basis for shaping, shaping different shapes of various products; such as diatomite toothbrush holder, diatomite coaster, diatomite chopsticks tube and so on kitchen and bathroom products.

- Easy shaping: the main skill of handmade diatomite products is time control, the production staff mix the material through stirring, Sheng, drenching, pushing, hanging, and other means, together with the auxiliary small scraper, quickly complete a diatomite product shaping, after a few minutes of condensation, a product is completed.

- Aesthetics: diatomite products present colorful colors through the assistance of inorganic color powder to meet the needs of different color lovers.

- “Live” is another characteristic of handmade diatomite products: they can be matched with other materials, such as bamboo, metal, wood, plastic, etc. Once held in the hands, the whole product is “alive” and more vibrant.

Handmade Product Process Chart

A: Airdrying Process Flow

01

Product Design

Customers will provide product design schemes and drawings according to their own market needs.

02

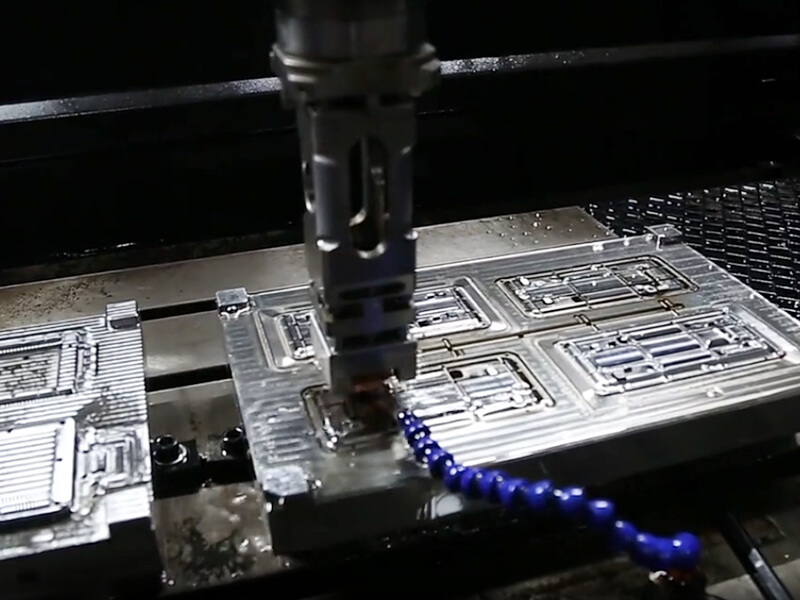

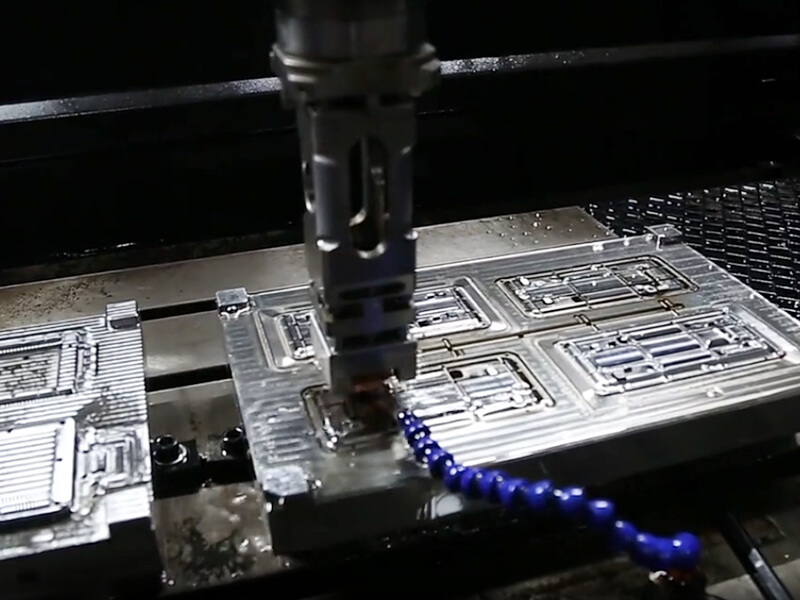

Mold Making

MAKE 3D modeling according to customer design scheme.

03

Sample Mold Making

Make sample mold according to 3D mold for customer adjustment and confirmation.

04

Production Bulk Molds

After confirming the sample mold, make the steel mold to turn the mold production mold.

05

Ingredients

Mix raw materials according to the ratio.

06

Mixing

Put the prepared raw materials into the mixing equipment for full mixing.

07

Air Drying

The heat energy in the air will take the moisture away from the demoulded products so that we can obtain dry products.

08

Polishing

By rubbing the surface of the product with sandpaper, making it get smoothly.

09

Inspection

In order to ensure that each product is in line with the quality standards and customer requirements, the QC personnel carry out inspection on all products.

10

Finished

After QC inspection, defective products are eliminated, and qualified products are awaiting packaging.

11

Packing

Pack the products according to the customer’s operation instructions.

12

Warehouse

Stack them on the pallet, and send them to the finished product warehouse for shipment.

B: Sintering Process Flow

01

Product Design

Customers will provide product design schemes and drawings according to their own market needs.

02

Mold Making

MAKE 3D modeling according to customer design scheme.

03

Production Bulk Molds

After confirming the sample mold, make the steel mold to turn the mold production mold.

04

Ingredients

Mix raw materials according to the ratio.

05

Mixing

Put the prepared raw materials into the mixing equipment for full mixing.

06

Adobe Preparation

Prefabricate the mixed raw materials into adobe.

07

Molding

Put the prefabricated adobe into the mold for demoulding.

08

Sintering

The demoulded products are placed in a high temperature environment of about 780 degrees for 6 hours of heat treatment, so as to improve the density of products and increase the strength of products.

09

Polishing

By rubbing the surface of the product with sandpaper, making it get smoothly.

10

Finished

After QC inspection, defective products are eliminated, and qualified products are awaiting packaging.

11

Packing

Pack the products according to the customer’s operation instructions.

12

Warehouse

Stack them on the pallet, and send them to the finished product warehouse for shipment.

Send Us Message

Send an inquiry now and get free samples