Wholesale / OEM / ODM

Stone Bath Mat

- Customizable Products

- Certified Quality

- Competitive Pricing

- Reliable Supplier

- BSCI Audited

The Main Features

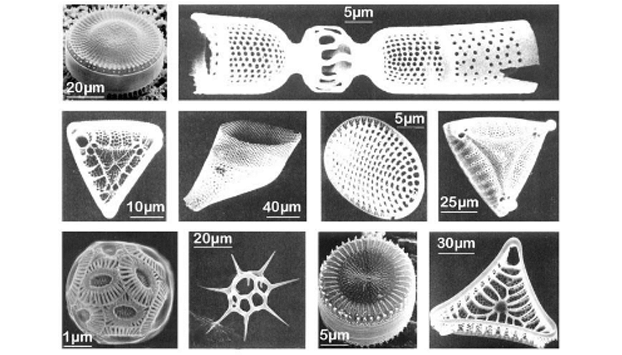

Environmental Protection Material

Millions of years of diatomaceous earth are rich in many beneficial minerals.

Absorbs Water and Dries Quickly

The porosity reached above 90%. Instant water quickly dry, and the bathroom is no longer wet.

Anti-mold, Anti-bacterial

Diatomaceous earth contains naturally weak alkaline substances, Anti-mildew, anti-humidity, and antibacterial.

Durable and non-slip

16 quality crafts, exquisite carving,

Non-slip and easy to clean.

Bulk Production Process Video

15 Questions You Don’t Know About Diatomite Mat

Already Applied

Goodbye, Wet Footprints;

Goodbye, Dirty Floor;

Goodbye, Horrible Bacteria!

Customer’s Evaluation of Us

The company’s diatomite floor mats are very popular, and the quality and price are very good, which has kept my business hot, and I have recently ordered three 40-foot cabinets.

From the beginning of contacting your company, after several months of negotiations, we finally reached cooperation. As a product of this new material, we are very interested. Thank you for your sincerity and I hope that our cooperation is happy.

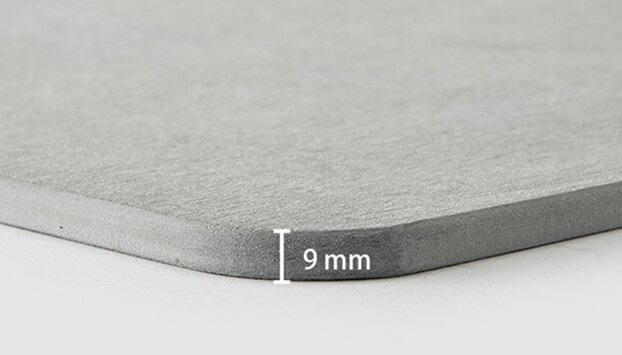

| Product Name | Diatomite Bath Mat (Conventional) |

| Size | 600*390*9 mm |

| Graphic Box | 610*405*25 mm |

| Carton Dimension | 640*440*305 mm |

| Color | White Blue Green Pink Gray |

| Net Weight(1 pcs) | 2.1 kg±0.25kg |

| Qty of Package | 10pcs |

| Packaging | Bubble bag + Inner Box + Graphic Box + Carton |

| 20″/40HQ | 3200pcs / 8300pcs |

| MOQ | 3000pcs |