Diatomite Mat Manufacturer

- Anti-bacterial rate of 90%, dries fast at your feet – no complaints from customers about wet feet.

- Do you hate stepping out of the shower onto a wet bath mat?

- Not anymore! We have the innovative bath mat made out of natural diatomite that absorbs the moisture out of your wet soles, and dries those little piggies in seconds.

- Ease of maintenance – Over time, while it sits in the bathroom, dries up.

Hot Selling Products

Diatomite Mat Features

Quick Drying

Diatomite mats are made from diatomaceous earth, a highly absorbent natural material that quickly wicks away moisture, leaving the mat dry within minutes after use. This prevents the growth of mold, mildew, and bacteria that thrive in damp environments.

Antimicrobial Properties

The natural composition of diatomaceous earth makes diatomite mats resistant to the growth of bacteria, mold, and mildew, providing a more hygienic bathroom environment.

Durability

Unlike fabric mats that can wear out quickly, diatomite mat are incredibly durable and long-lasting, often lasting for years with proper maintenance.

Easy Maintenance

Diatomite mats can be easily cleaned by wiping them down with a dry cloth or sanding them periodically to remove any buildup. They do not require frequent washing like fabric mats.

Slip Resistance

The textured surface of diatomite mats provides excellent traction, reducing the risk of slips and falls in the bathroom. Many also come with anti-slip backings for added safety.

Eco-Friendly

Unlike synthetic mats, stone drying mats are sustainable and made from 100% natural and eco-friendly diatomaceous earth.

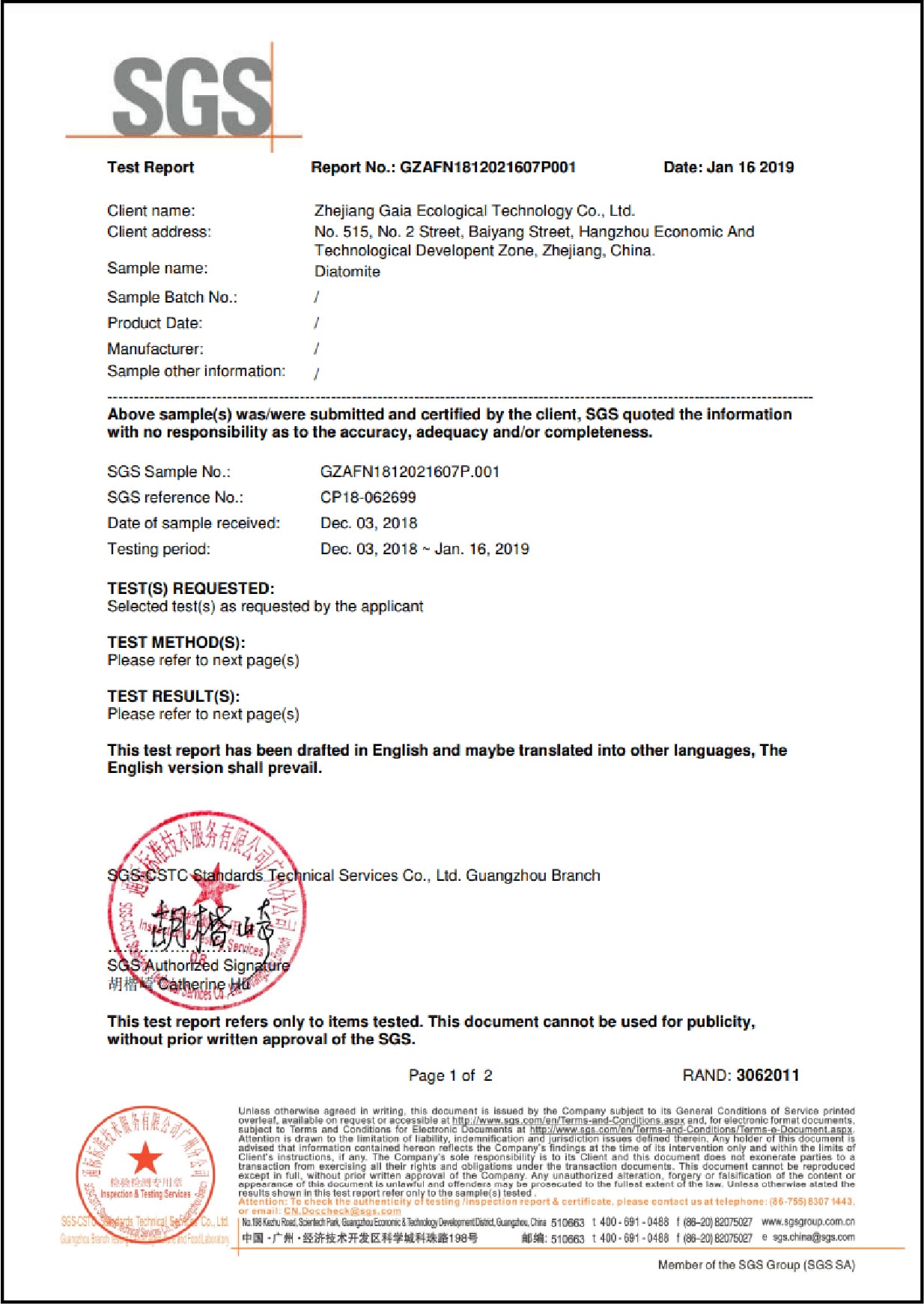

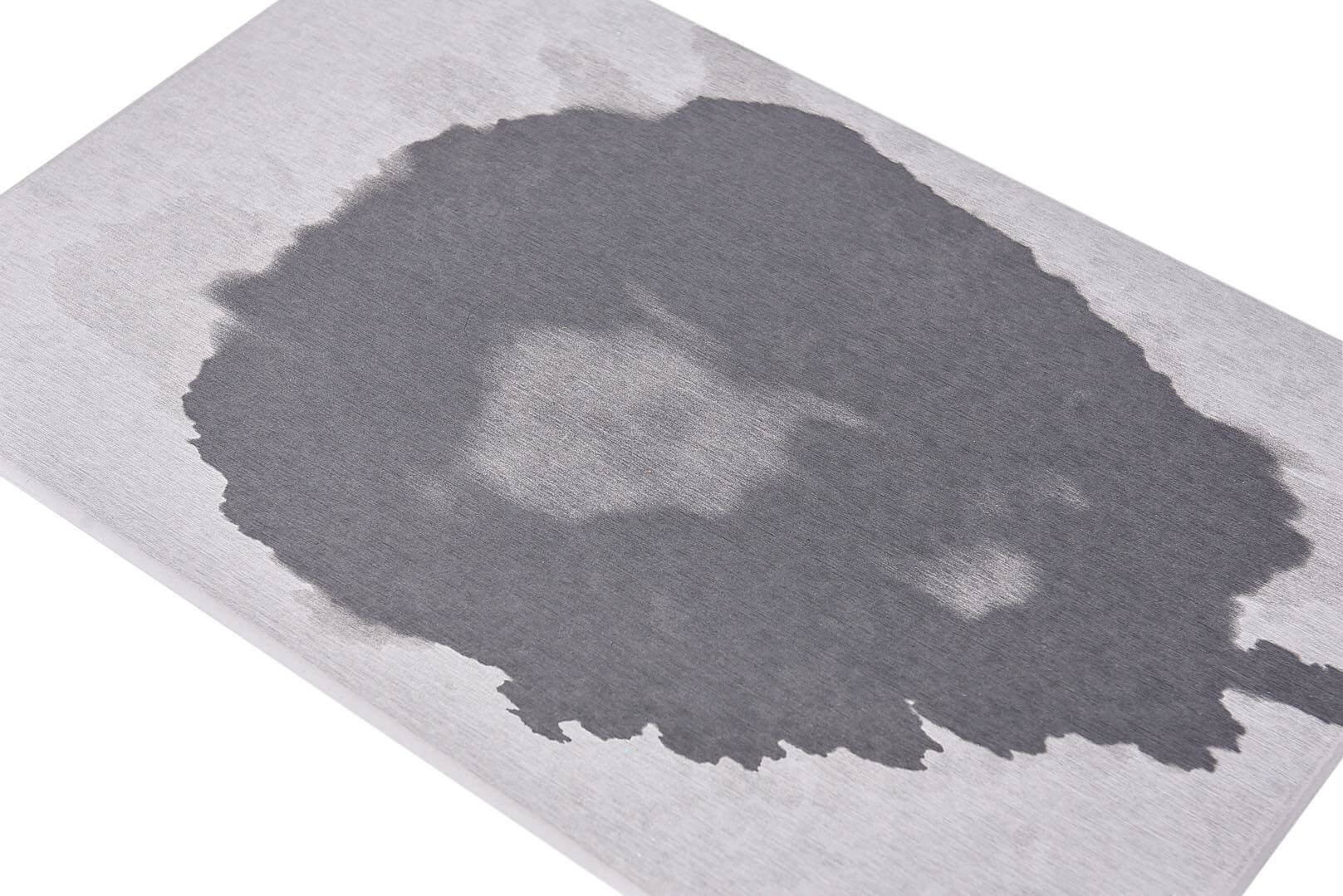

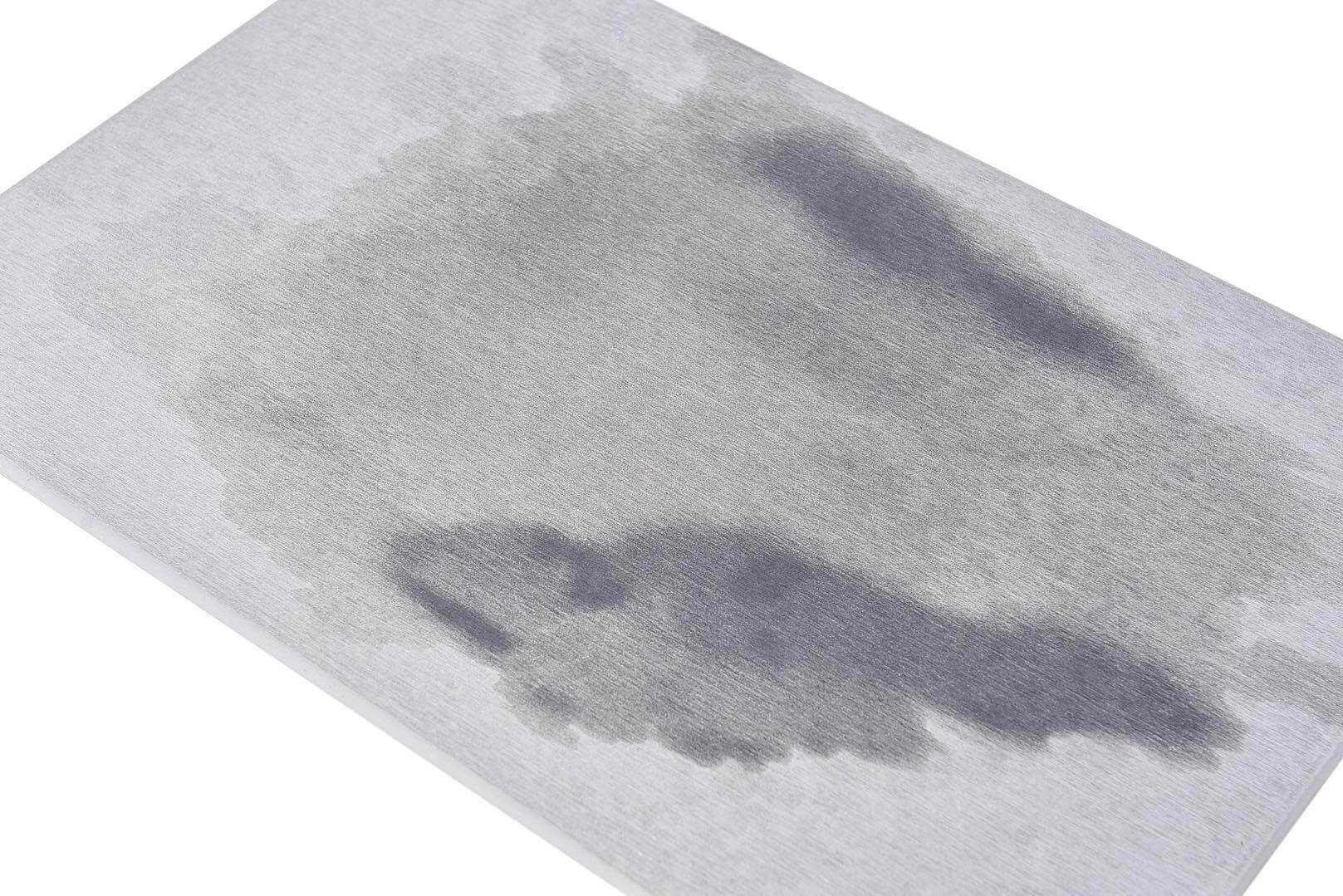

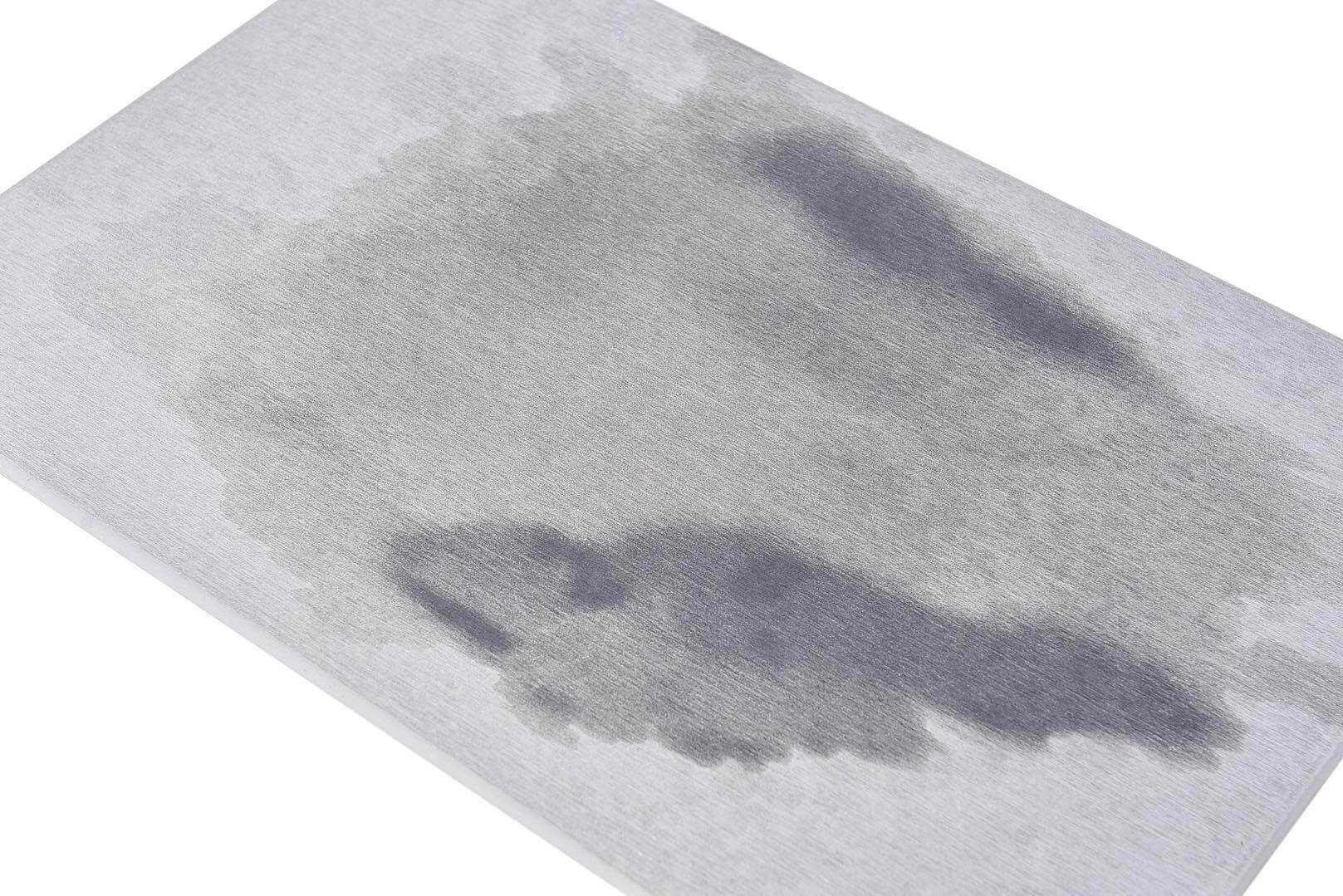

Water Absorption Process

The diatom remains have numerous tiny pores on the surface of the microscope.

Up to 90% porosity surface absorbs excess moisture quickly

Providing conditions for super absorbentness of the floor mat

Can absorb water 2-4 times its own weight

Stepping on moment

After 1 minute

After 5 minute

After 10 minutes

After 15 minutes

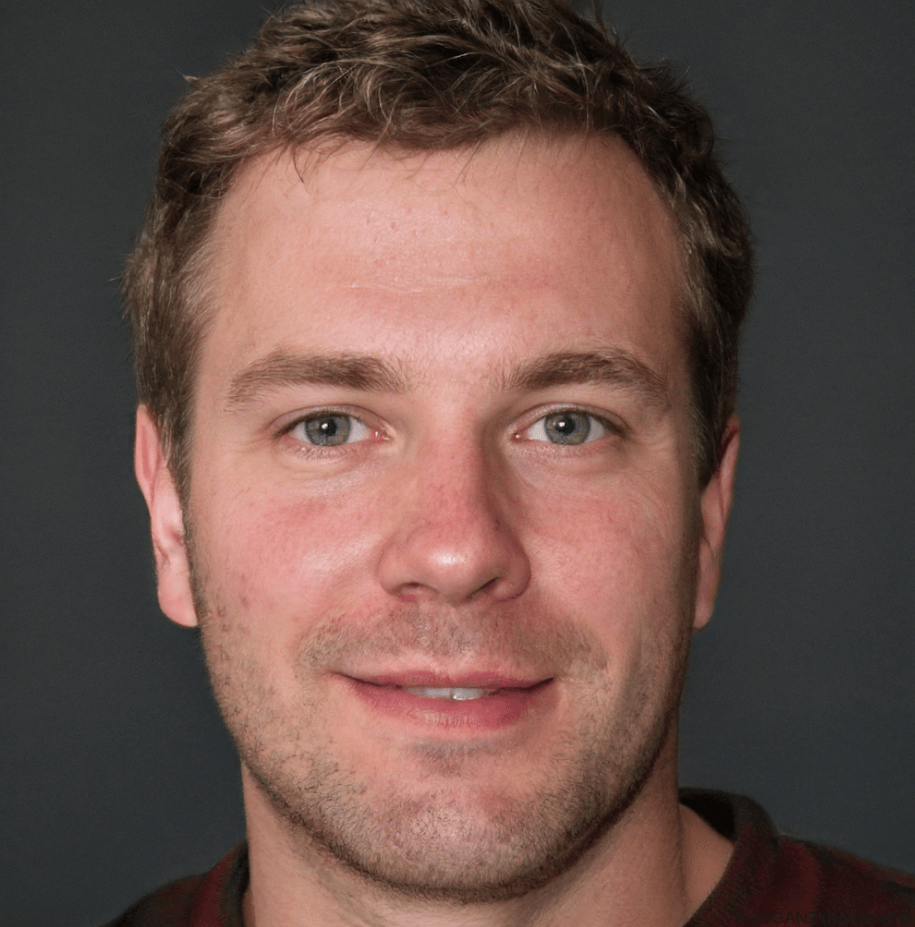

Our Client Testimonials

“The company’s diatomite floor mats are very popular, and the quality and price are very good, which has kept my business hot, and I have recently ordered three 40-foot cabinets.”

James Parker

*** Xplort Limited.

“From the beginning of contacting your company, after several months of negotiations, we finally reached cooperation. Thank you for your sincerity and I hope that our cooperation is happy.”

Mary Ellen

*** ko Co., Ltd.

“This was my first time buying from GAIAECO, and I must say, I’m impressed. There’s attention to detail and customization options are unparalleled. They truly understand the need for modern bathroom mats.”

Devin Mueller

*** International LLC.

Materials & Manufacturing

Material Overview

Brief overview of the main materials used

Diatomaceous Earth

- Diatoms are single-celled plants, one of the earliest protozoa that appeared on Earth, living in seawater or lake water.

- Diatoms are tiny, and there are large differences between diatom species, ranging from 3.5 microns to 300-600 microns.

- The cell wall of diatoms is composed of SIO2, a delicate and fine mesh with an extremely complex and precise structure.

- The diatom cell wall’s composition and special morphological structure are the significant characteristics of diatoms, which determine the characteristics and wide application of diatomaceous earth.

- Large specific surface area

- Strong adsorption

- High chemical stability

- Strong water absorption and permeability

- Fine, loose, light, porous

- Poor conductor of heat, electricity and sound

Plant Fiber

- We use Canadian Softwood Pulp, the wood used for pulping is more than 50 years old, it has long fibers, soft material, thin cell wall, this kind of pulp has a large aspect ratio, the fiber can produce a relatively large fiber interweaving ability during papermaking, so its strength is better.

- It mainly has a certain effect on the strength and toughness of the forming of diatomite boards.

Manufacturing Process

Eco-friendly and sustainable manufacturing process

1st step: Ingredients

Put the diatomaceous earth, calcium silicate, quartz sand, and plant fiber into the filling barrel respectively and stir.

2nd step: Forging

Using the flow slurry method, it is made of about 20 layers of materials superimposed, after 5000 tons of forging.

3nd step: Making board

Cut into a rectangular shape of 1.22×2.44m.

4th step: Autoclave pre-curing

Put it into an autoclave at a high temperature of 200 degrees and 10 standard atmospheres, and bake for 48 hours.

5th step: Drying

Bake in the drying line for 30 minutes.

6th step: Sanding

Use a sand machine on the front and back of the board to make it clean and textured. The number of meshes for sanding is 80 meshes on the front and 80 meshes on the reverse.

7th step: Cutting

The diatomite board is fixed by airtightness, the cutting is automatic through a computer setting program.

8th step: Engraving

According to customer needs, make the program and carve it into different patterns.

9th step: Polish

The four edges of the cut product are made into R angles. The four sides of the diatomite stone mat can be made smooth by grinding.

10th step: Printing

UV printing is carried out according to the customer’s customized requirements and the manuscripts provided by the customer.

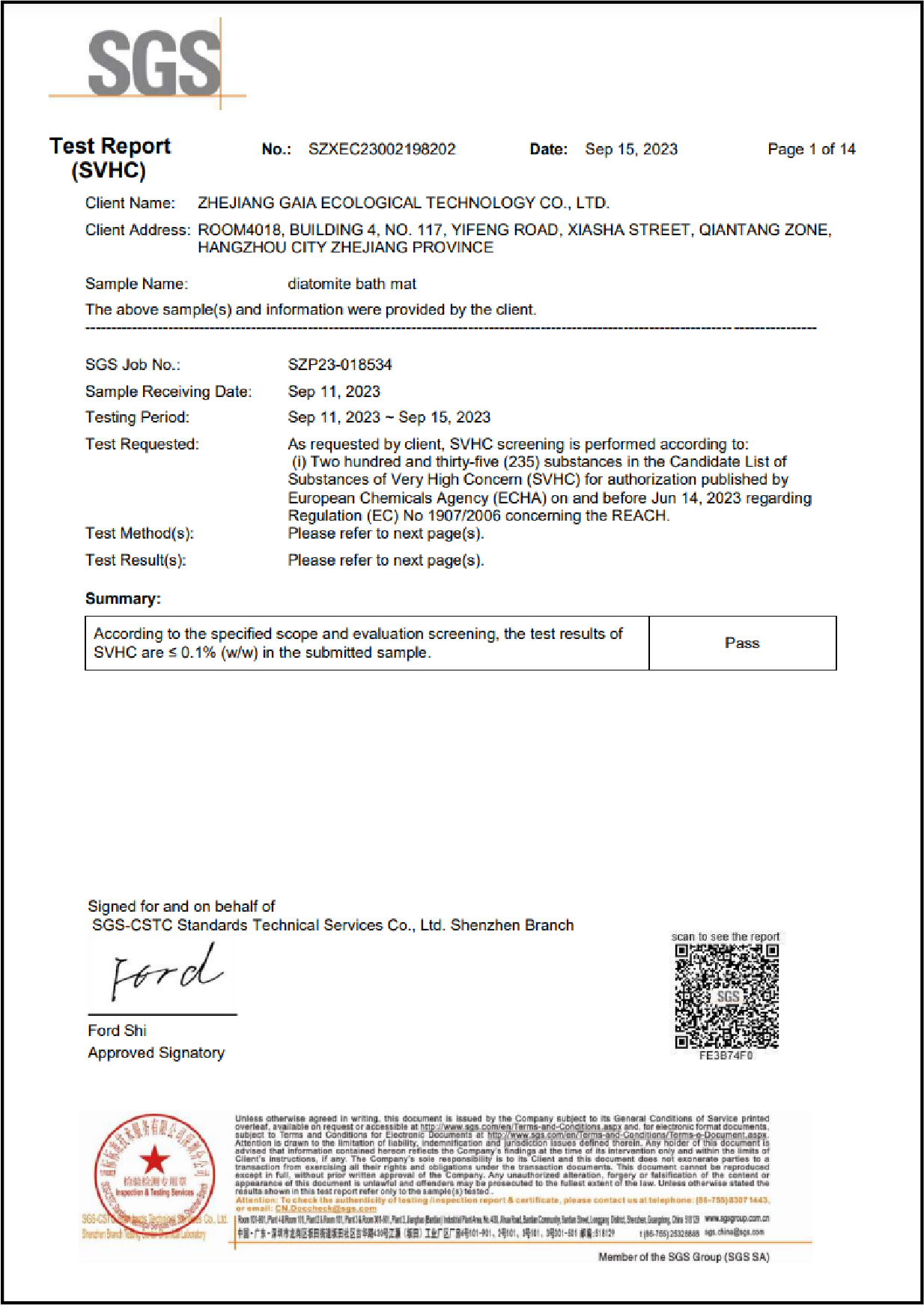

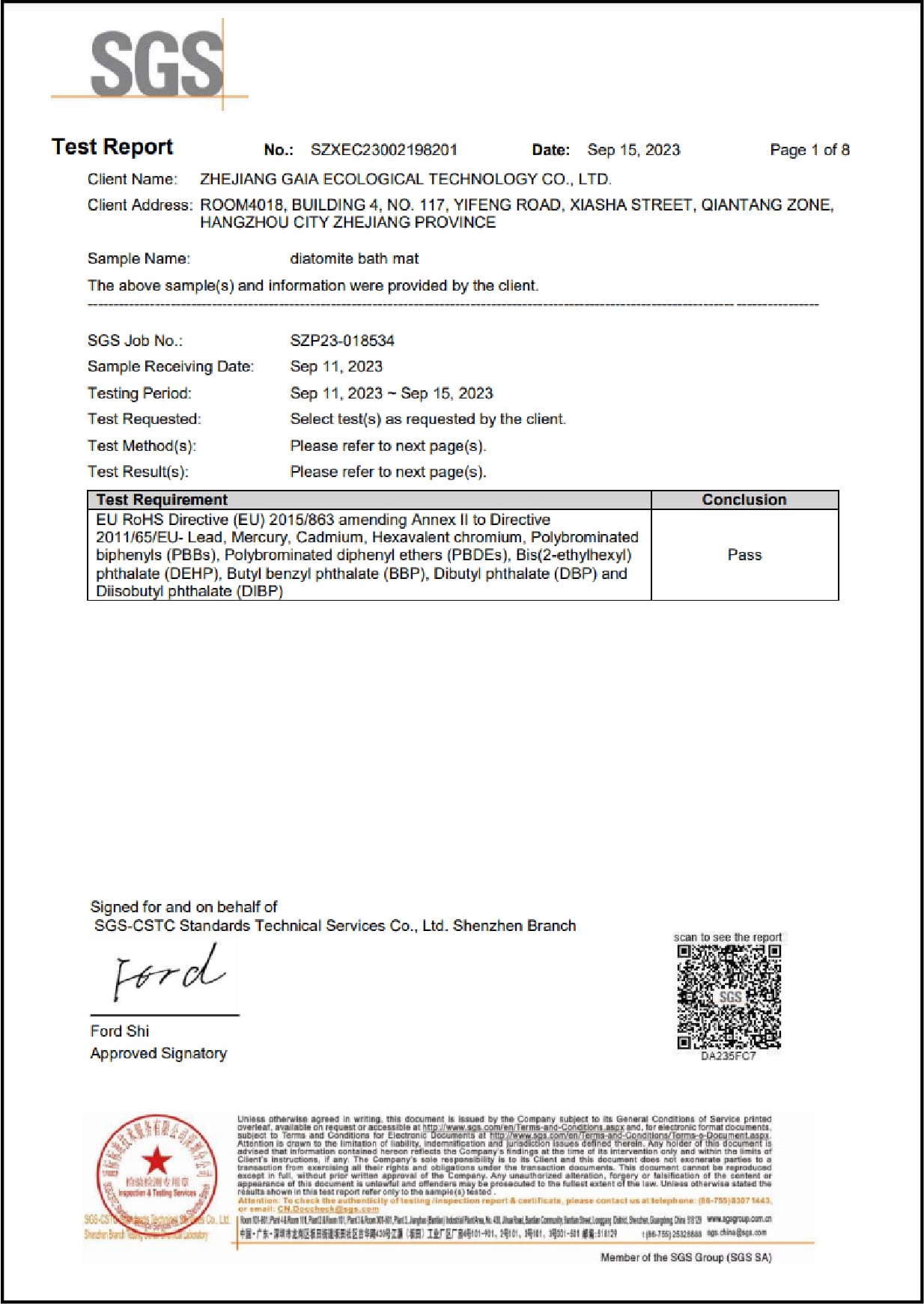

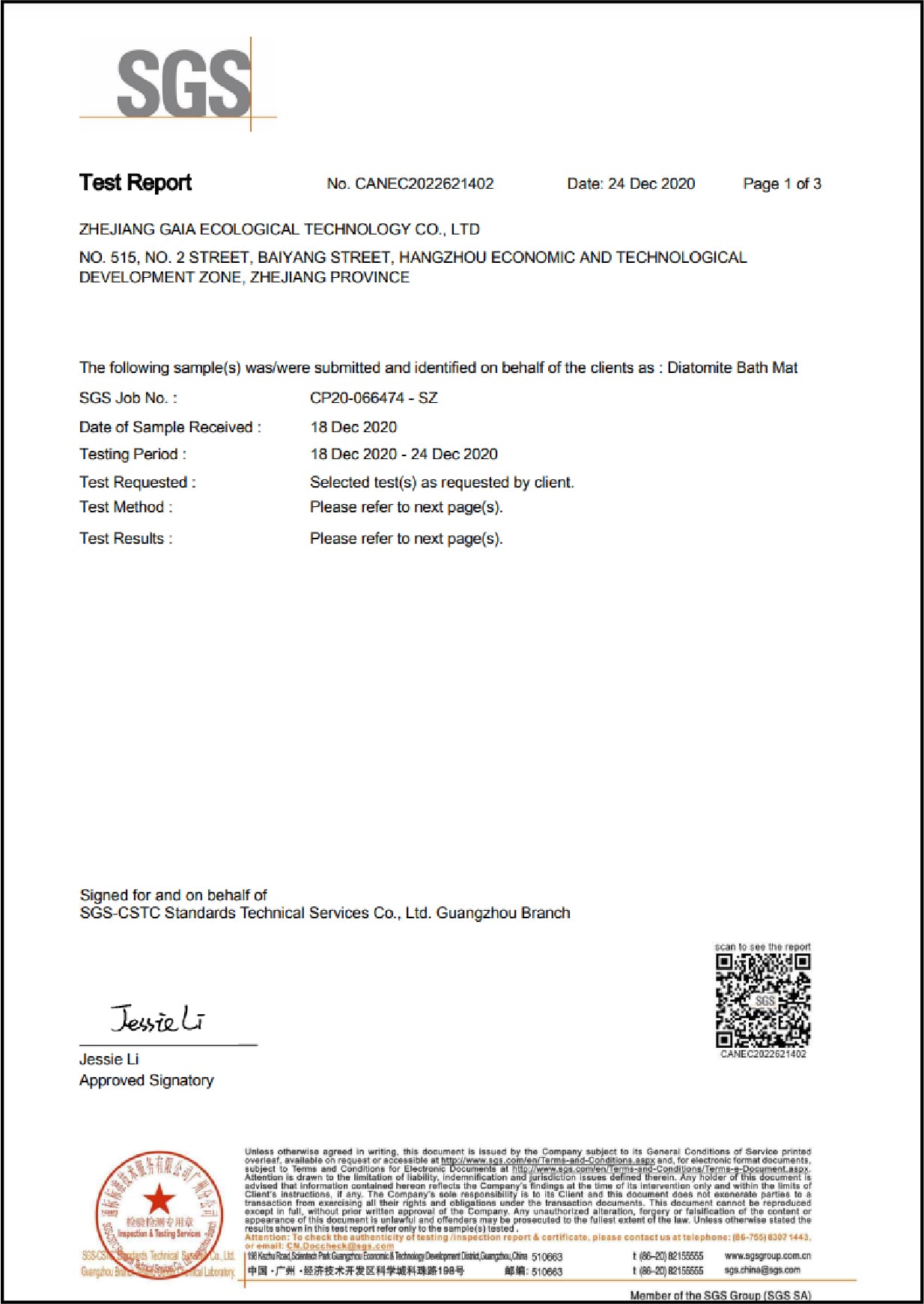

11th step: Testing

Our factory conducts 100% self-inspection, and quality inspection can also be carried out by customers or third parties to ensure quality.

12th step: Packing

Packing is done according to the different requirements of each customer. Usually, we have two ways: online packaging and offline packaging.

Customizable

to your needs

Color Available

We have these 6 colors: white/light grey/dark grey/pink/green/blue, but currently the most popular in the market are these 3 colors: white/light grey/dark grey.

White

Light Grey

Dark Grey

Pink

Green

Blue

Style Available

We currently have 5 types of production processes, you can choose the one that suits your company’s business development.

Original

Printing

Engraving

Printing & Engraving

Fold

Size Available

We currently have 5 regular sizes: 800×500×9 mm / 600×390×9 mm / 550×400×9 mm / 450×350×9 mm / 385×290×9 mm. The size can also be customized according to your requirements.

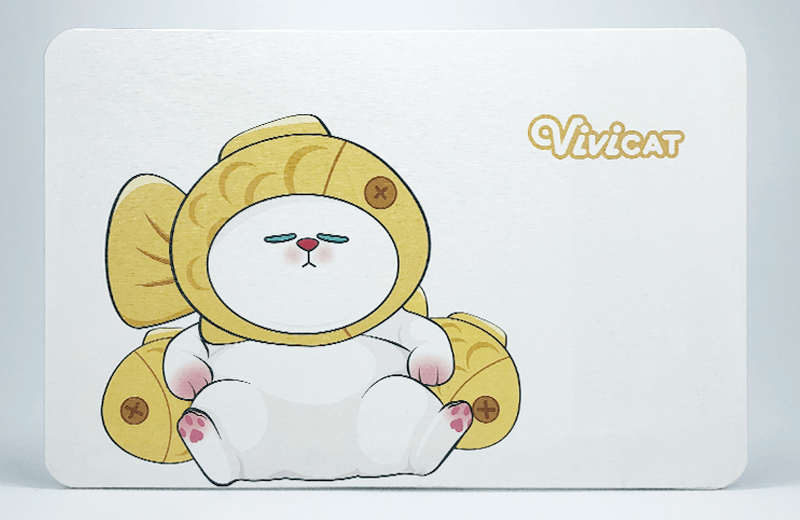

Customizable Logo, Shape, Pattern, Package

The logo, product shape, pattern, and packaging can be customized according to your requirements. You only need to provide the design manuscript. AI format is available.

Logo Design

(Printing)

Logo Design

(Engraving)

Pattern Design

(Any Pattern can be available)

Pattern Design

(Any Pattern can be available)

Quality Control Process

Our company’s commitment to quality and safety standards

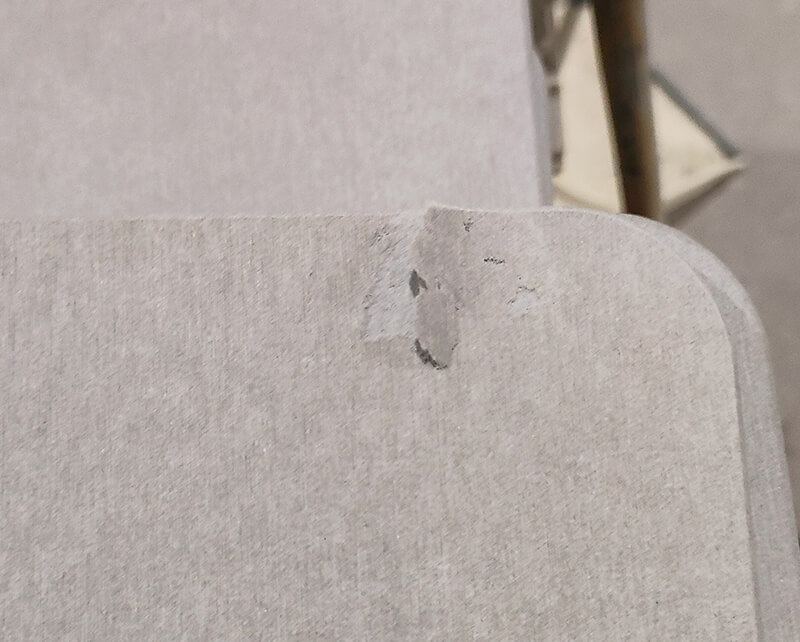

Visual Inspection

- There is no obvious color difference between the same batch of products and the confirmed sample.

- The product can not be stained with blood, insects, glass, hair, or other things.

- There must be no visible crack, peeling, or delamination phenomenon.

Peeling Phenomenon

Delamination Phenomenon

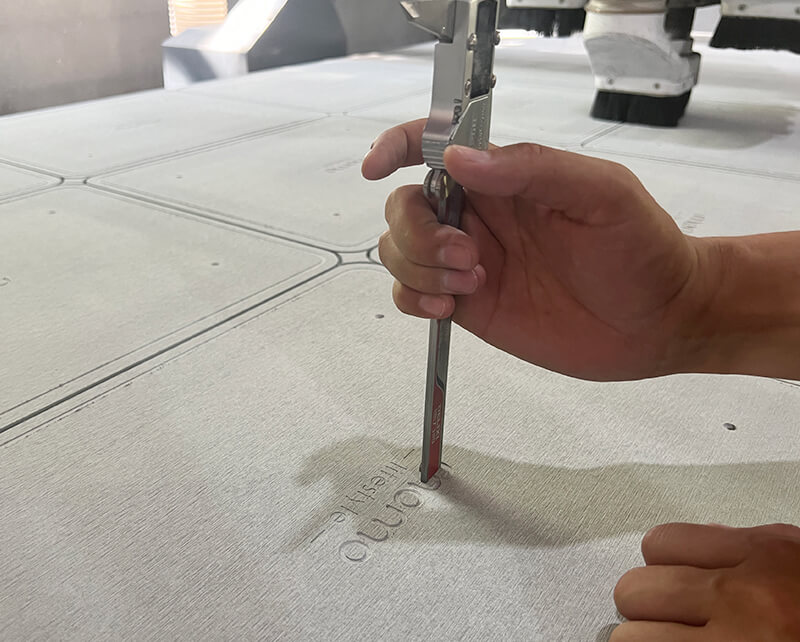

Dimension Inspection

- Inspection tool: calipers/electronic scale/ruler

- Mill depth of cut, Ridge width, etc.

- Length or width, Thickness: 9mm ±1mm

Dimension Inspection-Package Size

Dimension Inspection – Engraving depth

Dimension Inspection – Carton size

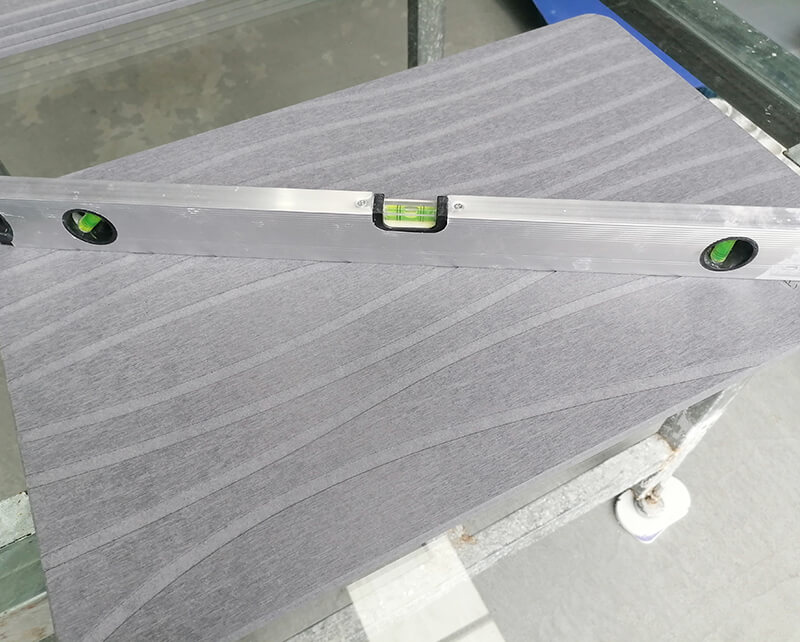

Cosmetic Inspection

- Tools for test: a) Big-size glass panel; b) Level tester.

- Test: Put stone mats on the glass panel surface and make measurements by level tester, if the gap is over 2.0mm, sort

out and count it as a major defect. The quantity for the filler gauge measurement test is order qty/200, for example, the order qty is 4000 pcs, and 20 pcs will be for the filler gauge measurement test. - Visual check: Put stone mats on the glass panel surface and take a visual check, if a bow issue is found, sort it out and

make a gap measurement by level tester; if the gap is over 2.0mm, sort it out and count as a major defect. A visual check

will be performed for all sample sizes at the final inspection stage.

Level tester-straight line

Level tester-diagonal line

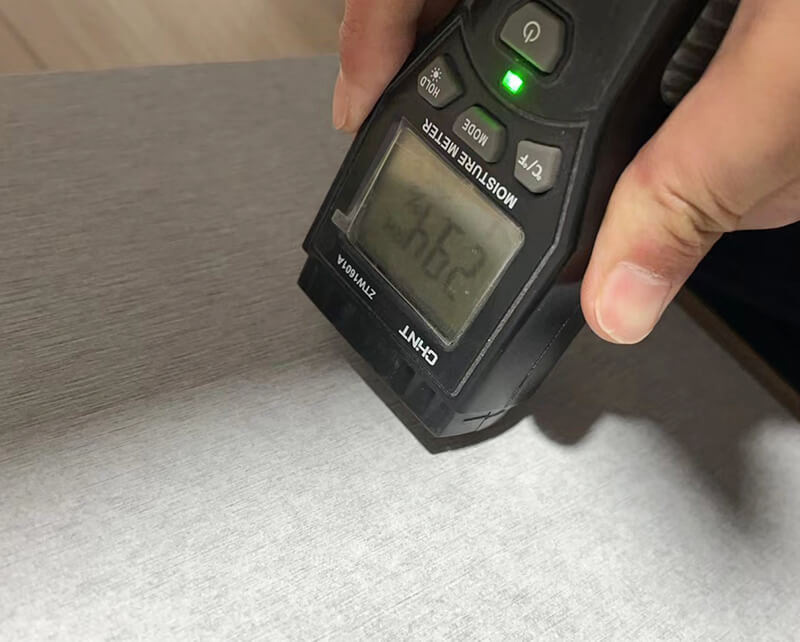

Water Absorption Inspection

- Water absorption test: spray method.

- Spray 20cm away from the surface of the product three times, and take no specular reflection after absorbing water as the benchmark of absorption. Water absorption speed ≤15 seconds. Water droplets condense on the printing surface and pattern parts after encountering water, so the water absorption test does not refer to the printing surface then pattern parts.

Moisture Content Test

Water Absorption Test

Packaging Inspection

- Printing contents should be clear, content correct, position correct;

- Damaged/deformed/moisture/dirty not allowed;

- Printing color and pattern refer to the signed samples.

Packaging Inspection-1

Packaging Inspection-2

Packaging Inspection-3

Fast, Reliable Delivery

Time is critical for your business. That’s why we guarantee fast production and on-time delivery for all orders. We can ship anywhere in the world, ensuring your products arrive on time, every time.